About Sheet Metal Fabrication Service

Sheet metal fabrication is the process of turning thin sheets of material into parts, often for end-use applications like chassis and enclosures. Depending on the design of the product, different fabrication processes are used to create the final component.

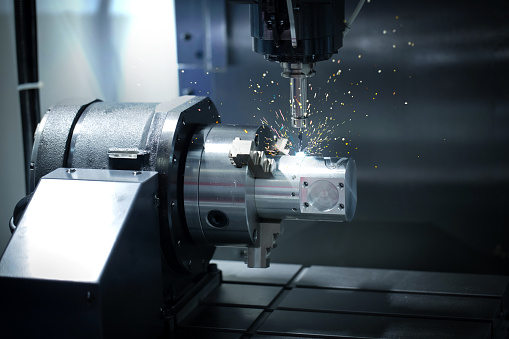

Fabrication begins with a design model in CAD (computer-aided design). This step is important because it enables the manufacturer to identify any problems and areas of improvement that may be required for optimal production. Once the design has been established, it is translated into machine programs that ensure accurate fabrication of the final product.

Next, engineers use a variety of cutting and forming methods to keep the original shape and size of the part. These include laser cutting, waterjet cutting, shearing, and flame cutting. Be sure to click here for more details!

Once the part is formed, it will undergo additional fabrication processes to make sure it is of the highest quality. These include bending, punching, and stamping.

Plating is another finishing process that we often use on sheet metal components. This coating allows us to protect the surface of the metal, which helps prevent corrosion and oxidation. It also gives the finished product a better appearance and improves its durability. To know more about metals, visit this website at https://www.huffingtonpost.com/entry/why-central-bankers-have-_b_11736654.

Welding is the final fabrication process, fusing two or more components together with heat. It is a versatile process that can be applied to many types of metal, including aluminum, stainless steel, brass, and copper.

The most common type of welding is arc welding, but there are also other processes that can be used. Some welding techniques include MIG, TIG, and SMAW.

Before hiring a fabrication company, it is essential to check the credentials and experience level of their team. A company with a strong track record of satisfied customers is more likely to give you high-quality results. You can find these qualifications on their website or through references from previous clients.

A reliable fabrication company will be accredited by the relevant body, ensuring that they adhere to standards of craft and quality. This certification is essential because it will establish the company's reliability and help you get a superior result from your project.

When it comes to choosing a fabrication company, you should look for specialists who have years of experience and specialized in the product that you need. This is because the more experience a contractor has, the more likely they are to produce high-quality products.

It is also a good idea to check their portfolio of work. This will provide you with an idea of their experience in various projects and help you gauge how they handle different types of materials.

A company at https://syncfab.com/3d-printing-services/ with a solid track record of high-quality and satisfied customers is more likely to give you the best possible result for your custom metal fabrication project. It is also a good idea to look for a company that offers services like CAD design and programming. This will ensure that the design for your sheet metal component is a precise representation of your requirements and will help you avoid any mistakes during the manufacturing process.